Space Shuttle Launch Complex 39-B Construction Photos

Page 24

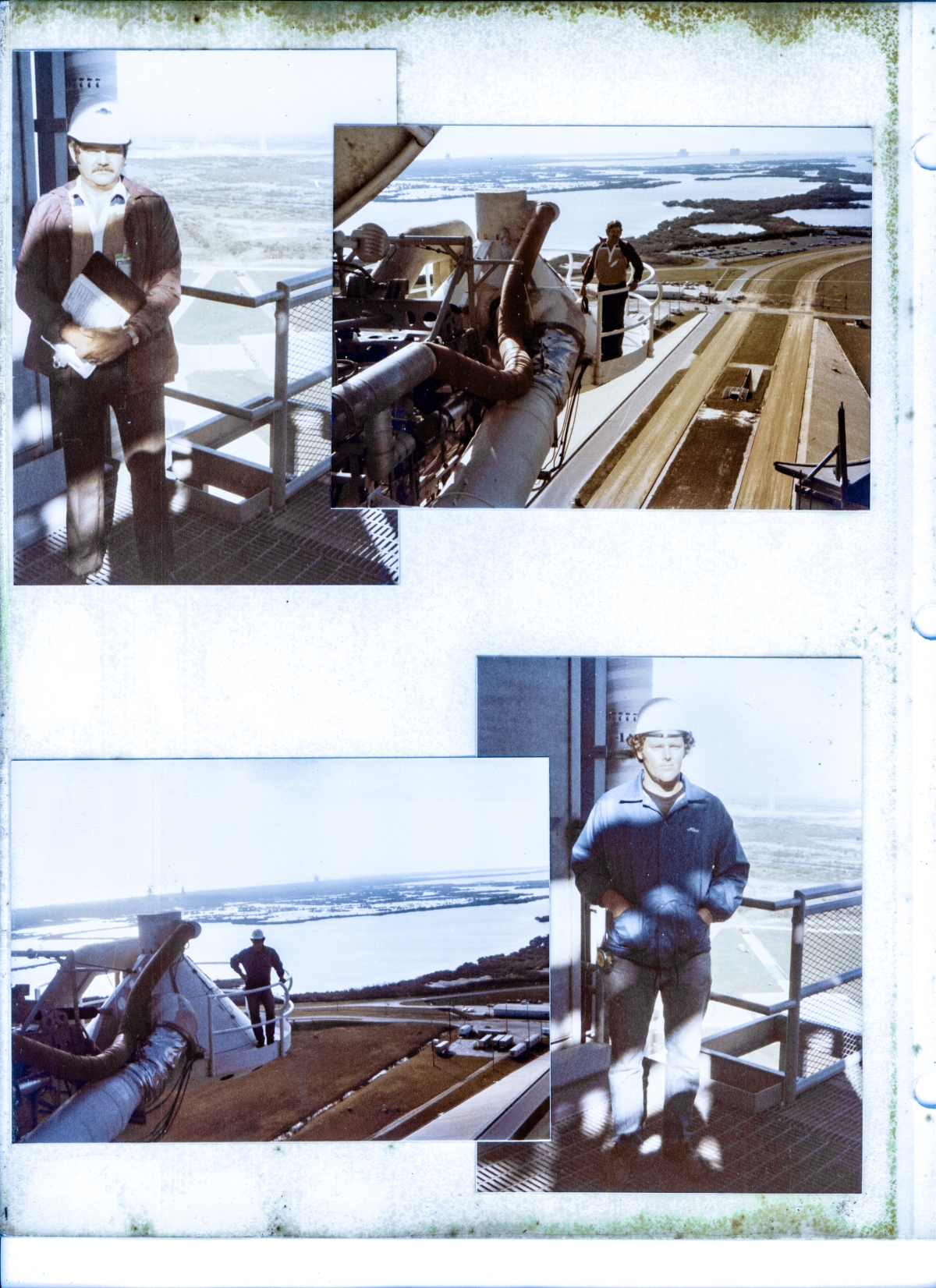

Steely-eyed Missile Men (Original Scan)

Steely-eyed missile men, goofing around like little kids, placing themselves in life-threatening positions just for fun, hanging out on the GOX Arm Beanie Cap at Pad 39-A.

Additional commentary below the image.

Background Info:

As mentioned elsewhere, Jack Petty (BRPH Tech Rep) and I would frequently go over to A Pad (which was up, running, and live at the time) to see how issues that were bedeviling us over at B Pad had been dealt with and handled.

The pads were certainly not identical twins, but they matched each other pretty closely, and as a set of fraternal twins, they had much in common.

The structural drawings for Pad B were washoffs (go to page 12 of the spec) of the structural drawings for Pad A, and as such, inevitably failed to contain significant amounts of information regarding the innumerable existing site differences, alterations, changes, tweaks, and adjustments to things that had accumulated after the finalized design of the structure had been rendered into its initial package of fabrication drawings, erection drawings, and specifications. A "washoff" is a drawing that has had areas on it erased, and probably, but not necessarily, replaced with something else, but the rest of the drawing is the exact same rendering of something that was done earlier, perhaps as the original drawing, perhaps not. Washoffs were used all the time back in those days, owing to the fact that the use of washoffs eliminated the outrageous time, expense, and schedule impacts that would be incurred if the whole damn thing had to be designed, engineered, and rendered, from scratch.

That kind of thing happed all the time back then, and it happens all the time today, too, although the use of blueline drawings, diazo machines, and all the rest of it has long since faded into oblivion, replaced by digital renderings. That said, the smell of ammonia brings back fond memories to this day, of the diazo machine that stood against one wall of the field trailer, slowly unfurling another nice big 28 by 40 inch F-size blueline print of some damn thing or other, soft, limp, and still damp to the touch as it continued outgassing all the marvelously toxic fumes embedded within it, eventually reverting to its previously dry-paper look and feel.

Lots of times, the only thing that would get washed off would be the title block, and lots of times only a small part of the title block would be washed off and replaced, and sometimes that could be as infinitesimal a change as washing off the "A" that followed "39" and replacing it with a "B" to indicate that the drawing applied to Pad B, and not Pad A. And not one single other thing in the entire complex of lines, shapes, letters, and numbers that covered the whole damn great big sheet of paper would be touched.

In their defense, they did save a substantial amount of time and money that would have been spent uselessly duplicating things, but every once in a while, things would bite you squarely on the ass, and whenever that happened, the "cognizant authorities" (read: NASA and whomever may have been working for or under NASA) would invariably attempt to throw the blame (and, more importantly, the cost, and the schedule impact) on to the shoulders of the poor saps who had to employ the goddamned washoffs, trying to build the miserable sonofabitches their own goddamned launch pad to their own goddamned specifications, even though those specifications were riddled with no end of sneaky "gotcha!" stuff that could not possibly have been picked up in any kind of real-world review of the plans and specs during the bid process.

And the bastards knew this but they always came right at you with it, every damn time, anyway.

My own personal favorite story regarding the depths of fuckuppery that can occur when the engineering from one project was transferred to another (which is the point where washoffs come in to the picture, ok?), consisted in the transfer of the as-builts to NASA at the end of the job when I worked for Sheffield Steel, wherein we fabricated and delivered the the entire structure of the RSS as well as no small quantity of other stuff, too. (Please note: The structural drawings that were furnished to Sheffield Steel as an integral part of the contract that was issued to fabricate and deliver the structural elements that would become Pad B were themselves a set of washoffs from Pad A, so you can see that it quickly becomes a case of wheels inside of wheels inside of wheels..... and things can, and do, get out of hand far more rapidly than you might imagine at first glance.)

As a job this size goes on, no end of changes get incorporated into things. Changes as small as the alteration of a single bolt's length by a quarter inch, all the way up to cycloptic constructs weighing thousands of tons, and all points in between.

Some of the changes are deliberate, and reflect some alteration in the end use of the thing being constructed that requires the construction to change. Other changes are accidental, and result from the discovery of things in the plans and specs that are impossible to create as they are depicted on the drawings, owing to erroneous or missing information about the items in question and/or the precise nature of the surroundings in which those items must exist.

Either way, the original drawings and specs have to be altered to incorporate the change, and the process is exceptionally brittle and formal.

You don't touch a fucking thing until the requisite alterations have been formally documented and submitted to whatever "cognizant" (I often wondered why they always chose that particular word. It indicates a state of "having knowledge" or "being aware of" that was signally nowhere in evidence far too many times to count, but I digress.) authorities as you are working directly under, and then you sit tight and wait it out until the resulting change to the plans and specs is then handed back down the chain of command to you as a formal change order, whereupon you may then go out into the field and, as the ironworkers never grew tired of saying, "cut to suit, beat to fit, and paint to match."

The result of all of that (in some imaginary perfect world that I have never personally encountered in my whole life), is a properly-documented change to the plans and specs, precisely detailing the alteration, which becomes a part of the permanent record of the project.

One of my jobs out there when I worked for Sheffield Steel, who, as I said, furnished all the structural elements for the RSS, was to ride herd on the drawings, and the change orders to the drawings, in a way that resulted in our having a complete set of drawings that precisely detailed the as-built status of our part of the construction job that resulted in the modification of Launch Complex 39-B from its existing Apollo configuration to the Space Shuttle configuration that we built.

This set of "as-builts" was a Big Deal, and NASA was very excitable about things "as-built" and who could blame them? Fuck this one up with improper or incomplete documentation and you could easily wind up with a nightmare situation wherein a multi-billion dollar national asset was destroyed, along with any personnel or crew who may have been so unfortunate as to be too close to things when they went kablooey.

And as a part of all that scrutiny and obsessive attention to detail, NASA insisted that we have our altered "as-built" paper drawings reproduced as "mylars" as things went along, and then further had us deliver the entire set of mylars to them at the end of the job. Mylars are all about long-term storage and archiving. Paper drawings just do not have sufficient lifetime. They degrade. They turn into unreadable crud.

The project was big enough, and the drawings were numerous enough, that the resulting set of mylar as-builts, bundled up in rolls of fifty to a hundred sheets apiece, resembled nothing so much as a stack of cordwood, and each roll of drawings was equally heavy.

And I should know, because it fell to me to physically grab up as many rolls as I could in one go, and walk them over to the prime contractor's field trailer and formally submit them, have them checked and verified by a functionary over there, sign and receive my own copies of the formally-accepted submission paper, and then go back to our field trailer to schlep the next sixty or seventy pound batch of "cordwood" over to the prime contractor's trailer.

Lotta damn mylars!

And I personally delivered every single one of them to those bastards, so I know for an absolute fact that those formally-approved mylar as-builts were A.) successfully produced, submitted, and approved as being true and accurate by no less an authority than NASA itself in the first place, and B.) hand-carried to the "cognizant authorities" as part of wrapping up the job and getting our final payment for the work we did.

Years go by.

Literal years.

And then, by purest chance, I find myself right back out at the very same place once again, good old Launch Complex 39-B.

But this time I'm working for a different outfit, and we're adding a lot more "miscellaneous metals" and other things to the already-existing structure of the RSS, with which, once again purely by chance, I myself was deeply involved with the original fabrication and delivery of that which constituted the very structure upon which we were now adding more stuff.

Ok, fine. Whatever.

Except that it wasn't fine. And it wasn't whatever.

What it was, was a complete bid package, which we successfully bid upon and won, as per the precise, rigid, and ever-so-particular dictates of NASA's end of the Federal Acquisition Regulation (Go ahead. Click that fucking link. I dare you. And when you get to that first page, don't stop there. Oh no, do not stop anywhere, until you've not only read, but understood, the whole fucking thing, because it's the whole fucking thing that will be used to beat the living hell out of you, the contractor, once you've been so foolish as to bid on something that comes under its lawful purview, and never forget that there are far more of them, than there is of you, and each one of them is well-endowed with all of the time and malice that might ever be required to find some teeny-tiny sub-sub-paragraph dwelling far beneath some sub-sub-section, that can be used against you, should some difficulty or other arise that might impact the budget or the schedule of the job you were so foolish as to bid on in the first place.)

And yet somehow, armed as they were, to the teeth, they managed to find a way to fuck it all up so badly that they were unable to push the blame, and the cost, and the schedule impacts, off onto some other, weaker, party, although they tried, mightily, every single time, anyway.

Because they lost every fucking one of those as-builts, which never were found, recovered, or otherwise discovered in someone's basement or somewhere similar, and they had to revert back to the original washoffs from Pad A, and absorb the costs on a truly astounding number of the resulting inevitable change orders which of course had thereby became impossible to incorporate into the bid package, and which were further not even noticed in the first place by anyone over on their side of the house until it was far far too late, and which we dutifully banged our heads directly against, over and over and over, as we attempted to build the stupid sonofabitches their own goddamned launch pad, to their own goddamned deeply-flawed plans and specs, and endlessly found ourselves slap up against yet another show-stopping error on those selfsame deeply-flawed plans and specifications, waiting for the answer to be reinvented from scratch, yet again.

A grain of sand, as an example, if I may.

There was an electrical box. And it was up on the FSS fairly high somewhere, north of the elevator, and of course since this is the Space Shuttle, this fucking box was about six feet wide, two feet deep, and maybe nine feet tall. Big damn electrical box.

And it was oriented with its wide aspect facing east and west, placing a respectable amount of sail area directly in front of the Space Shuttle's deflected exhaust plume as it departed the pad.

And it had a substantial brace that held it firmly in place, which is how we, as structural people, came to be involved in matters.

The brace came in from above and to the side of the box, on its west side, from the main framing diagonal pipe bracing of the FSS as a pair of about-twenty-foot-long 3 x 3 x 3/16 or maybe even 4 x 4 x 1/4 angle-iron pieces (which themselves sported their own set of diagonal braces running in between them, vaguely resembling a Jacob's ladder or something) that spread out as they got farther and farther from their origin point on the FSS pipe diagonal, until they reached the electrical box, at which point they were far enough apart to meet the top corners of the box, and were welded to a large rectangle of more of the same-sized angle-iron framing that neatly tucked the perimeter edges of the box into the interior corner areas of that rectangular framework of angle-iron.

Ok, fine.

What's the big deal here, MacLaren?

Good question.

The pad was still under construction, no birds were flying yet, and that electrical box had been furnished and installed by the electricians at some point in the past, most likely prior to anybody ever thinking about exhaust plumes, sail area, or any of the rest of it, and it had a pair of full-size double-doors that swung open on piano hinges on each side of the box to fully expose the box's innards to whomever might need to get in there and fuck around with things.

Again, ok. Again, fine.

And we furnished the goddamned brace exactly as specified on the drawings, finish-coated and all, and when it came time to lift it up into place and weld it to the FSS perimeter pipe diagonal, and attach it to the box, it was only then discovered, by anybody, from the top (NASA), down (us), that the fucking thing was designed completely wrong, and that the perimeter angle-iron that attached to the fucking box, would be doing so on the side where the doors were, thus completely preventing anybody from ever opening those goddamned doors again.

Fingers were pointed, accusations were hurled, and that part of the job stopped dead in its tracks while the various parties maneuvered for greatest effect against their adversaries.

Oh god, not this again. Please.

And the dance was danced, yet again, and as part of that dance, me and Jack rolled on over to A Pad, and took a look at things over there, and discovered that on A Pad, the fucking doors on that box faced in the opposite direction! The whole box, over on B Pad, had been rotated 180 degrees for some unknown reason, and apparently nobody had ever noticed a thing, and just went right on, business as usual, using the A Pad washoffs, presuming things to be the same on both pads.

And of course the brace had to be taken down, torched, modified, rewelded and repainted, and then put back up on the stupid goddamned box on its other side so as it would not seal those doors shut.

Duh.

This is the kind of crap that went on every day. Every fucking day!

The whole sorry process had become so abysmal, and had spiraled out of control so swiftly, that instead of attempting to sort things out from first principles, they just more or less hand-waved myself and Jack Petty, who, as I've said earlier, was my counterpart at BRPH, a carte blanche "OK" for going over to Pad A to look at what had actually been done with real steel in the real world, sketch it up in-situ, and then return back to Pad B with that sketch which we then wrote up as a formal RFI and submitted as a "fix" which would get railroaded at high speed into the mouth of the system and then come spitting out the other end of the system as an approved change order, which, of course, they had to pay for and incorporate into the overall schedule of the project somehow without affecting the already set-in-stone end-date.

And oh yeah, if you think my memory is so phenomenal that I could actually remember the precise technical specifications of all those changes which appeared on all those as-builts that I originally schlepped over to the "cognizant authorities" when I worked for Sheffield Steel, then you're out of your fucking mind, ok? I was doing plenty good just to remember that something had been done here or perhaps there, but that was just about the extent of it, and maybe you'd be happy to risk the lives of the crew going up on the next launch from a pad containing a bunch of stuff that had been sort of just guessed at, but I sure wouldn't, and I sure didn't. And also please, also remember, that despite the less-than-stellar quality of my own less-than-photographic recollections of things, apparently those recollections were quite a bit better than any of the pointy-headed rocket-scientist engifuckingneers over on the other side of the house, none of whom apparently remembered anything at all about any of it. So don't go giving me any shit here, ok? Just forget that crap, 'cause I'm not having any of it from anybody, ok?

The system we were forced to invent was insane, but it worked. And so, you get as evidence, the above ever-so-innocuous-looking photographs of two intrepid stalwarts, over on Pad A, as they were going about their business of attempting to short-circuit the process of having to reinvent the wheel from dead scratch every single goddamned time, and instead get the best possible answer in the least possible amount of time, every time the fucking wheels fell off the goddamned cart, which was plenty. Gah.

Top Left: (Full-size)

Jack Petty, on the north side of the FSS on Pad A, view looking northwest, with Pad B in the distance behind him.

My mind holds zero by way of recollection of what we were doing over on Pad A this day. A complete blank. I do not even know if we were working on something up near the level of the Gox Arm on the FSS, or not. We may have been underground working in the catacombs for all I know, and, finding ourselves with a bit of free time, decided to go back up on the pad deck and then take the elevator to the top of the FSS. No recollection whatsoever. Apologies.

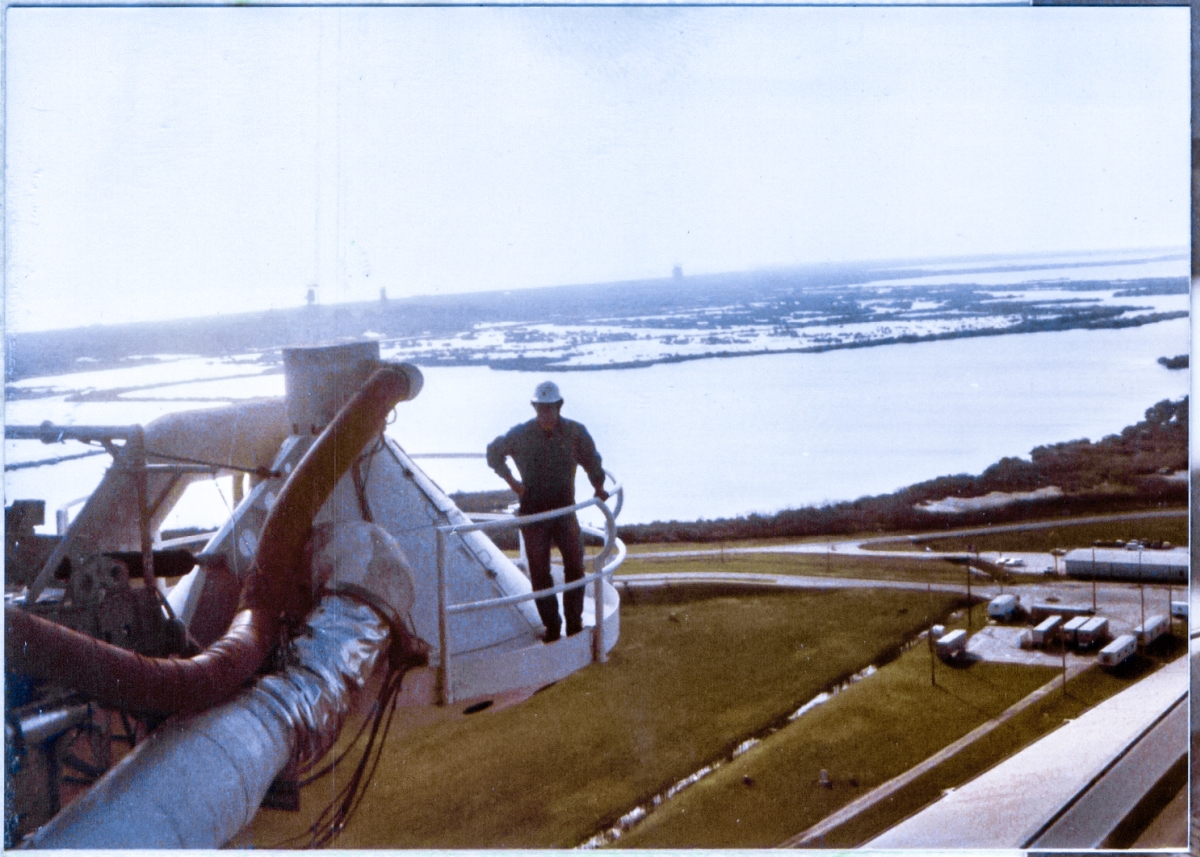

Top Right: (Reduced)

Jack Petty, standing out at the far end of things on the Gox Arm "Beanie Cap."

The "Beanie Cap" which is what everybody called it, and nobody that I can recall ever called it by its proper name "Gaseous Oxygen Vent Hood," was a surprisingly contrapted thing, considering the deceptive simplicity of its given job, which was to vent away any oxygen that was boiled off from inside the External Tank, in a safe manner that would preclude ice-buildup on the tank. Chunks of ice, falling off the top of the tank, in the direction of the Shuttle's ever-so-fragile TPS components, was a truly dreadful thing to consider, and it had to be eliminated before it could ever form in the first place.

The Beanie Cap had to be able to be swung out toward the ET in a lifted orientation and then lowered down flat and level like it's seen here (in it's retracted position, latched back to the FSS, by the way), or otherwise it would smash into the top of the External Tank, and that would never do, would it?

The requirements for systems power, mechanical actuators, no end of sensors and instrumentation, heated GN2 supply, as well as the vent that would actually be used to capture and duct away the troublesome build-up of gaseous O2, made for no end of crap out there where the Beanie Cap was bolted on to the end of the swing arm.

I distinctly recall what a fucking pain it the ass it was, trying to work through all that stuff in the hinge area between the Beanie Cap itself and the main body of the Gox Arm which supported it, attempting to get out to that too-narrow catwalk which surrounded most of the Beanie Cap, being damn sure to avoid any and all contact with every bit of it, without going over or through the unguarded (No handrail, Free Drop all the way down to the pad deck.) part of things in the process, which was not that far-fetched a possibility. There's an area in there, as you awkwardly try to thread yourself through, well off-center and well off-balance, hanging on to those few sparsely-scattered steel elements that could be trusted to hold you as you did so, where you've really gotta watch yourself.

In the far distance, you can see three large structures out across the wilderness of swamp and open water, and from left to right, they were, Pad 40, the SMAB (Wherein I also worked for a time, and of course encountered bizarre goings on, and which you can read about one little instance of: Here), and the VIB. Read all about it, if you'd like.

That this shot was taken on pad A is immediately apparent by looking at the sharp curve in the crawlerway as you go along it, getting farther away from the pad. On Pad B the crawlerway does not have that turn in it.

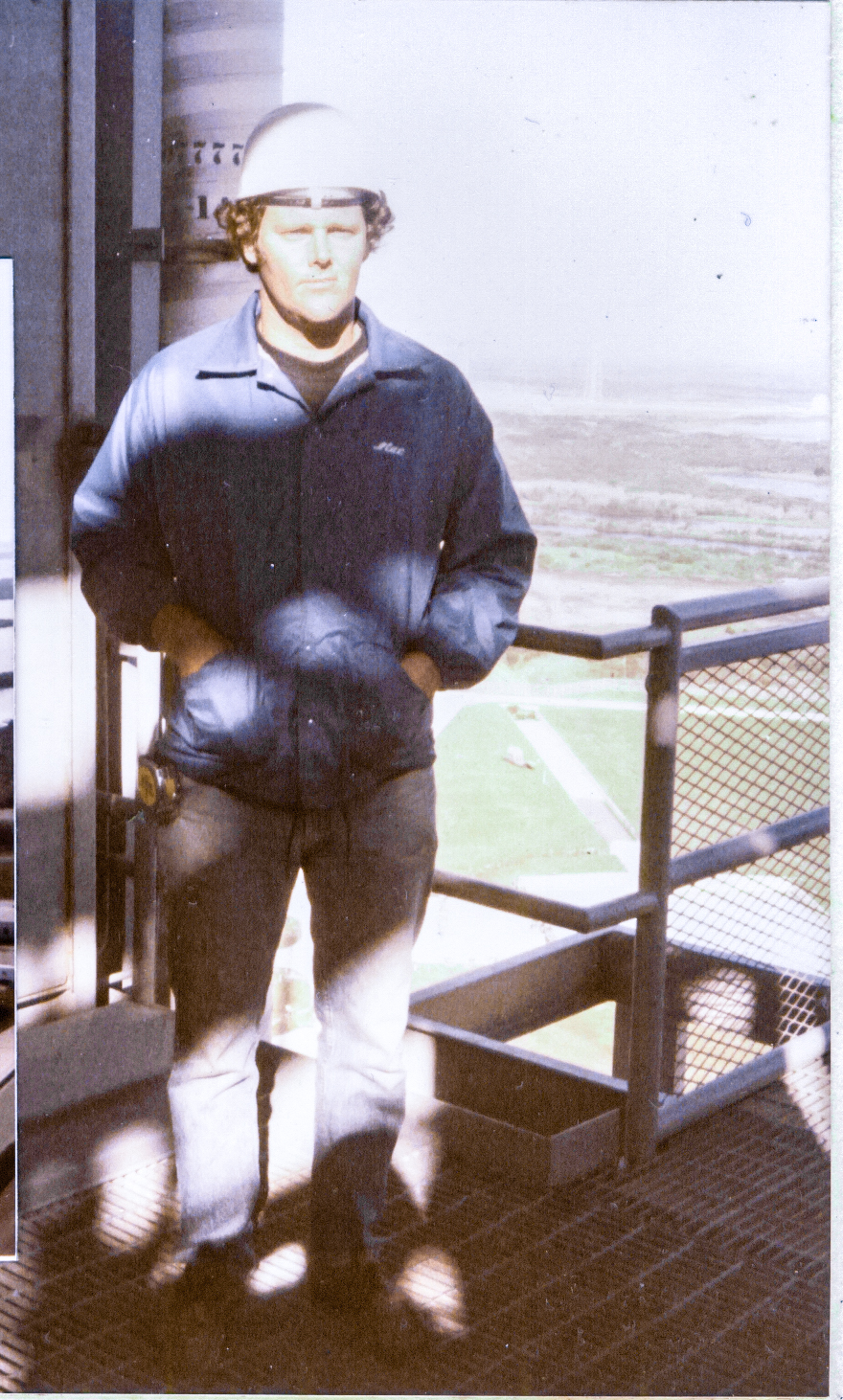

Bottom Left:

(Reduced)

And then of course we switch places, and Jack takes a shot of me doing the same thing.

In the distance behind me, in this shot taken from a slightly different angle, from left to right you can see the Mobile Service Tower of Pad 41, the Umbilical Tower of Pad 41, and the mated pair: MST/UT, of Pad 40.

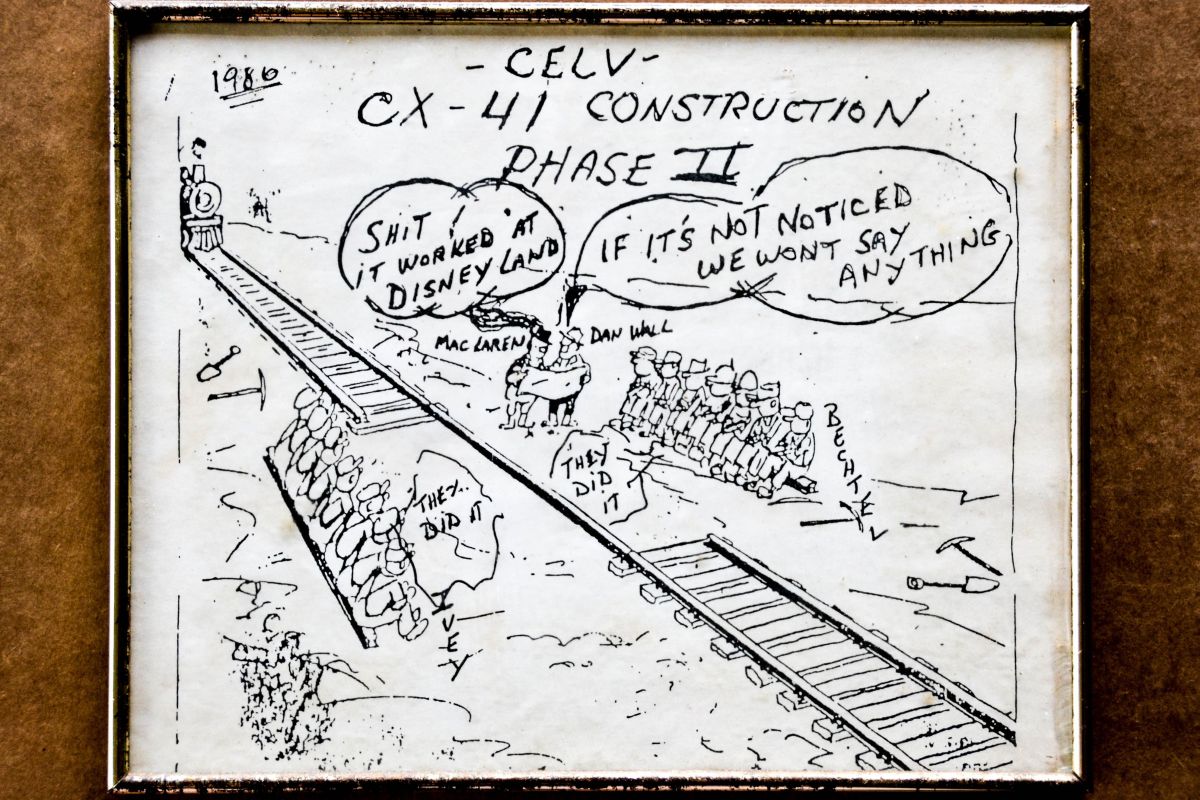

Once my work was done at B Pad, I would wind up over on Pad 41 for roughly five years, and the psychosis over there was much worse than the psychosis

at Pad B, but the inmates of that particular asylum were sufficiently delusional as to cause them to believe that they were the only sane ones, and this further caused them to disparage what was done over on the NASA side as shown in the image below

with "Disney Land" being a very uncomplimentary epithet for the Kennedy Space Center and NASA.

Pad 41, for all of its woes and difficulties, was the place where both Voyager spacecraft were launched from, on Titan III Centaurs, and that particular program will stand the test of time and be kindly looked upon by history, long after an awful lot of what everybody right now thinks is so important has faded into the cultural amnesia of worlds lost beyond ever recalling again. And yeah, I've got me a physical piece of that motherfucker too, and it's sitting here right next to me, even as I type these words.

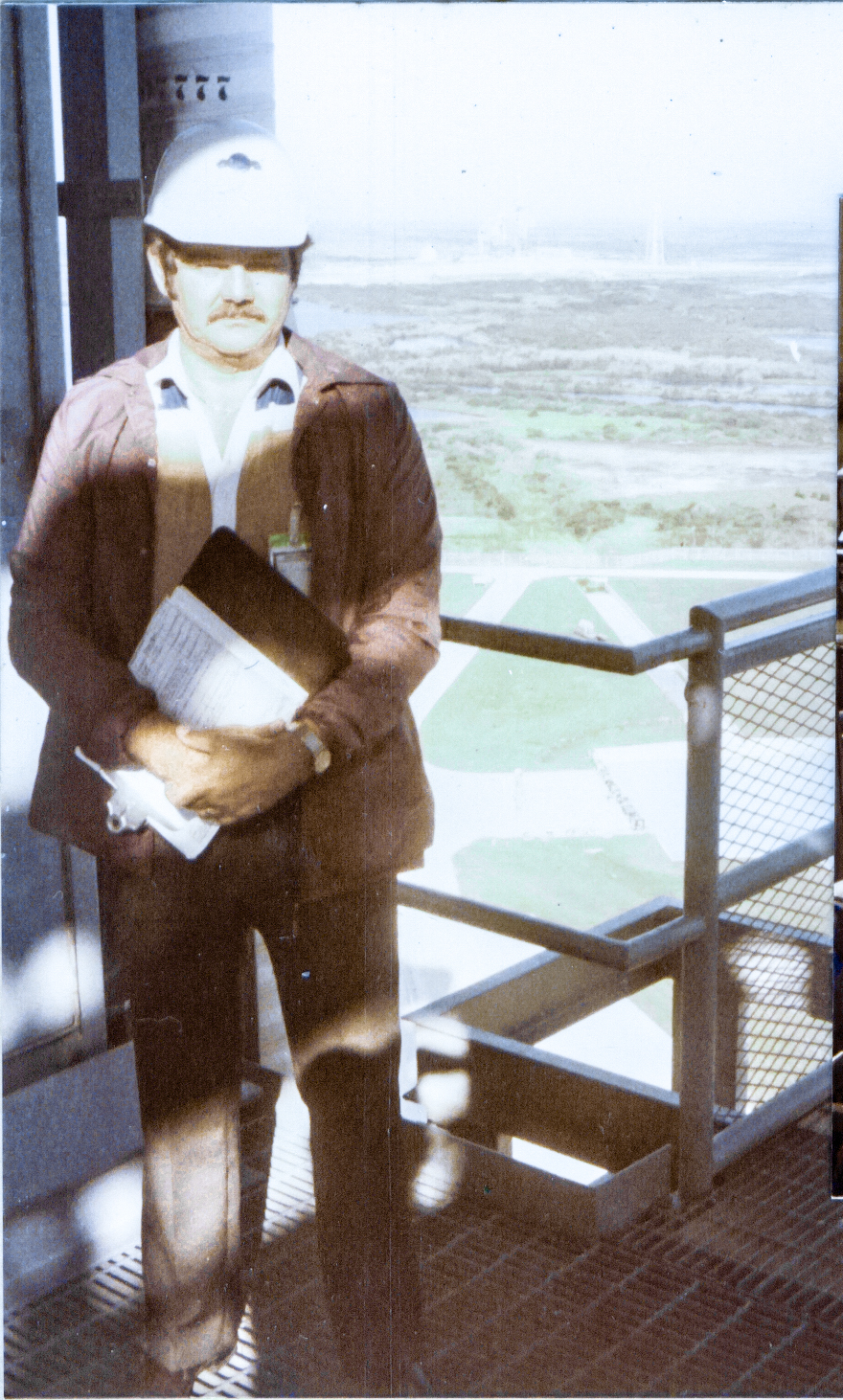

Bottom Right:

(Full-size)

And here we are, looking at some kind of James MacLaren that existed long ago in a world that has already disappeared forever, save a few tattered scraps such as this one.

Return to 16streets.comACRONYMS LOOK-UP PAGEMaybe try to email me? |